|

Formulaction are here to enhance your material formulation and curing with their new CurinScan Expert.

This is achieved via the ability to optimise your formulation ingredients, temperature, humidity, substrate and film thickness. Armed with a precise understanding of your formulation, including drying time, drying steps, and open time, you can then optimise your protocol with this unique, easy-to-use instrument. This is possible through: • Multilayer analysis • Temperature control • Humidity control • Realistic substrate • No wet-film thickness limitation • Wide range of experiment time scales. This instrument offers the following benefits: • In-situ and contactless • Sensitive to nanometer mobility • Surface and bulk measurements • Realistic experimental conditions • Easy sampling How does the CurinScan work? The CurinScan allows the monitoring of nanoscale mobility during the curing and drying process. Thanks to the Nanosacle Mobility Analysis (NMA), it identifies the drying and curing mechanisms (evaporation, packing, hardening, etc.) and their characteristic times (e.g. open time, dry-surface, drythrough, etc.). This measurement is in-situ, contactless and works on any type of substrate, including glass, metal, paper, and wood, from RT up to 250 °C. The measurement principle for the CurinScan is based on Nanoscale Mobility Analysis (NMA) and measures the structure’s (particles, polymers, pigments, etc.) Brownian motion. During the film formation or curing process, structure nanoscale mobility changes due to the change in the material properties, for example from liquid to solid. The in-situ analysis of the nanoscale mobility provides a full reading of the thermodynamic mechanisms and characteristic times. What are the other key benefits of the CurinScan? • Objectivity and accuracy to monitor the curing/drying • Determine the characteristic times of the film formation • Analysis from room temperature up to 250 °C with integrated humidity control • Evaluate the impact of formulation, temperature, substrate and thickness • Optimize the formulation and the manufacturing protocol. What industries can the CurinScan Expert be used in? This popular new instrument can be used for many applications, including: • Paints and inks • Coatings • Home and personal care • Cosmetics • Batteries and electronics • Chemistry and polymers. Where can I find out more information about the CurinScan Expert? To find out more information about the technical specifications and how this instrument can help you with your research and development, please call us today on: 01442 876777 or email: sales@fullbrook.com. You can also discover more over at our main website.

0 Comments

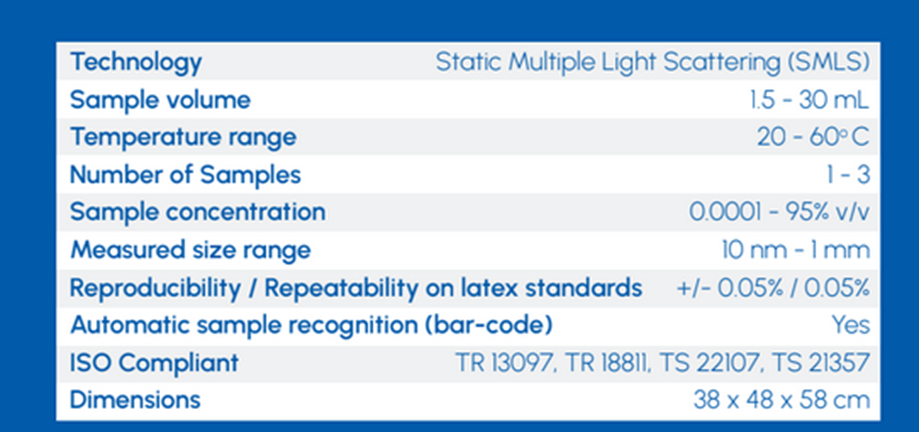

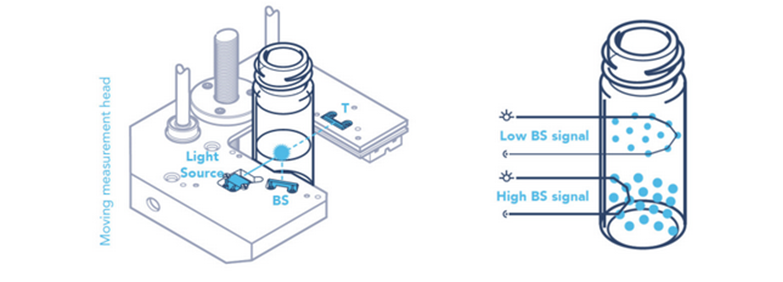

The Turbiscan is the leading technology to detect, at an early stage, all kinds of destabilisations such as coalescence, flocculation, creaming, and sedimentation. Emulsions, suspensions, or foams can be studied at a full concentration range (up to 95%v/v) without dilution or sample denaturation. Combining the SMLS technology with an in-depth knowledge of formulation science, the Turbiscan has become the most popular choice for a complete dispersion characterisation (i.e. dispersibility, shelf-life, and redispersing properties). The Turbsican TRI-LAB also benefits from the following: • Fast stability measurement on up to 3 samples – accelerate your stability measurement up to 1,000 times faster than visual observation. • Immediate Stability quantification – use the Turbsican Stability Index to rapidly quantify destabilisation kinetics. Take advantage of fast and simple product ranking, to enable straightforward decision making. • Assess the shelf life of potential new products under realistic conditions – the Turbiscan TRI-LAB offers real stability determination without mechanical stress or dilution (concentration up to 95% v/v). • Size Measurement – Static Multiple Light Scattering (SMLS) allows the determination of the mean particle size and its variation. How does Static Multiple Light Scattering work? The Turbiscan TRI-LAB uses SMLS to detect particle migration and size variation in liquid dispersions (please see the figure below). A measurement head moves over the cell height and works with 2 synchronous detectors: Transmission (T) and Backscattering (BS). This offers highly sensitive and reliable analysis of transparent to opaque samples even at high concentrations. T & BS signals are related to particle size and concentration and their variation is a sign of destabilization that is occurring. The Turbiscan Tri-Lab acquires both destabilization kinetics and mean particle size data at any given time. What are the other key benefits of the Turbiscan TRI-LAB? Additional benefits of using the TRI-LAB for your research and development include: • Fast and sensitive stability determination – the Turbiscan TRI-LAB is 1,000 times faster than visual control, offering real storage conditions with no centrifugation or dilution required. You can also rapidly study stability with 3 sample positions from 20 to 60 degrees using the accelerated stability analysis. • Gather a complete insight into formulation properties – this includes dispersion stability analysis (e.g. migration velocity, phase thickness, diameter kinetics), particle size (e.g. mean diameter and hydrodynamic diameter), dispersibility and redispersion testing (mean signal value comparison). • The simple and intuitive interface displays a global stability quantified with just one number to make decisions faster. This LCD screen also allows for instant reading. The adapted TSI scale for smart guidance produces a high quality valuation. Which industries can the Turbiscan TRI-LAB be applied to? The TRI-LAB has recently been used across the following sectors: • Home and Personal Care • Food • Paints and Inks • Pharmaceuticals • Oil and Petroleum • Electronics. Where can I find out more about the Turbiscan TRI-LAB? For more information about how this popular instrument can help your formulation research and development, please contact us today on: 01442 876777 or email: sales@fullbrook.com. You can see the full technical specifications for the TRI-LAB below:  One of our most popular instruments at Fullbrook Systems is the Turbsican DNS, which offers a unique platform to help you reformulate the future.

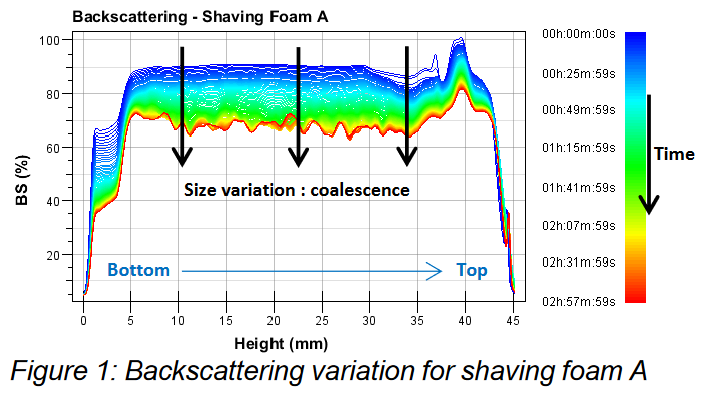

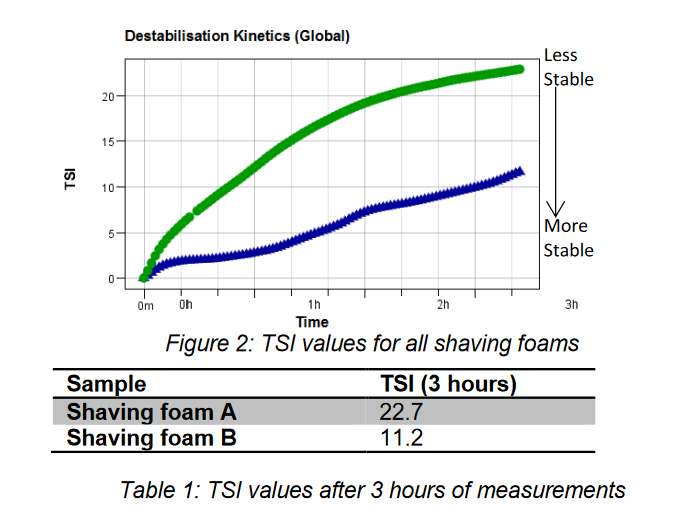

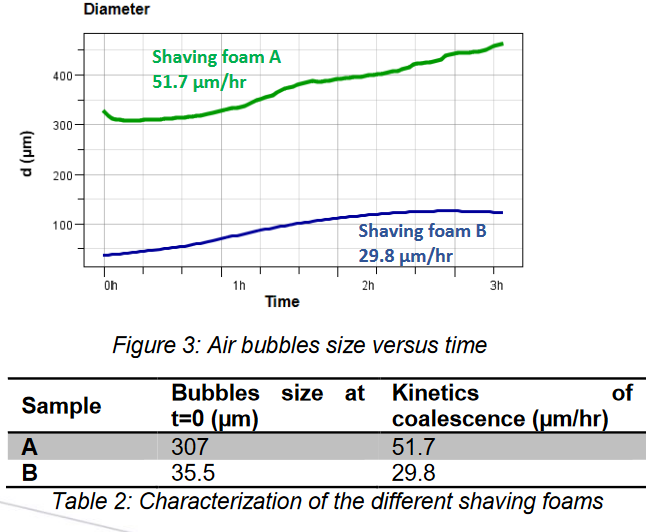

This ready-to-use tool is ideal for dispersibility studies, and carries the following benefits: • No-dilution particle size kinetics – SMLS technology determines particle size in a native state, up to 95% v/v. • High frequency online measurement – this allows you to measure while mixing directly in the measurement vial or while working in an external reactor. • A 2 in 1 Turbiscan – determines the stability and dispersibility of your new product with the same instrument and/or in the same experiment. How can the Turbiscan DNS help with dispersibility and stability studies? Formulaction’s Turbiscan DNS is a piece of technology at the forefront of direct stability measurement, revealing new opportunities in particle dispersibility studies. This factor forms the foundation of successful formulation, and is crucial for higher quality dispersions. To enable this, the Turbiscan DNS is built with the two features of dispersibility and stability, which allows for dispersion characterisation from the first stage of formulation, through to the entire shelf life of the product. What are dispersibility and stability? Dispersibility is the ease of dispersing an article into a liquid in terms of the spatial distribution and the particle size. Studying dispersibility of a new formulation is vital for optimising key parameters such as: • Colour • Therapeutic efficacy • Film homogeneity • Sensoral properties. Monitoring and quantifying dispersibility is also useful for other parameters, including: • Suspension ability • Solubility • Emulsification • Foaming • Solvent optimisation (e.g. Hansen parameters) • Digestion studies. Stability ensures that the initial structure and the end-use properties remain acceptable within the desired time and in the storage or shipping conditions. By carefully optimising dispersion stability of your products, you can guarantee a long shelf-life and customer satisfaction. What is Static Multiple Light Scattering (SMLS)? The Turbiscan DNS uses SMLS to detect particle migration and size variation in liquid dispersions due to the association of two highly sensitive photo detectors placed in transmission (T)[Light which passes straight through the sample]; and Backscattering (BS) [Light that is scattered out of the samples] modes and a moving reading head. The sample can be scanned while at rest, for stability measurement, or under agitation/on-line for dispersibility studies via the mixing function (T-MIX) and circulation function (T-LOOP). Due to its ability to work at rest and under agitation, it’s no surprise that this platform is a popular choice for fully characterising new formulations across a range of industries. What are the other benefits of the Turbiscan DNS? As well as the above, this instrument also offers: • Online particle sizing with two options: analysis under agitation or under circulation connected with an external reactor. • No dilution for certain particle sizes (10nm to 1mm) • Direct and instant monitoring of processes, from seconds to months. • Quick and quantified shelf-life testing, with stability measured up to 1,000 times faster than visual control • Detection and quantification of the whole destabilisation process • Real stability testing with studies performed under actual storage conditions, with no centrifugation or dilution required. • A 2-in-1 instrument that allows both dispersibility and stability to be measured during the same experiment set up. What sectors can the Turbiscan DNS be applied in? Popular applications of this instrument include: • Chemicals • Food • Paint & Ink • Pharmaceutical • Oil & Petroleum • Electronics. For more information, or for a free, no obligation quote, please email: sales@fullbrook.com or call: 01442 876777. What is a foam? A foam is formed by entraining gas in a liquid. The stability of a foam needs to be matched to its purpose, a shaving foam may only last for a few minutes, a foam filler may need to last hours or even days. With shaving foams, the foam must remain stable when applied to skin at body temperature (37°C). This means that the kinetics of the foam breaking is a fundamental parameter for the formulator. However, this characterization is very difficult to perform due to the inherent fragility of the foam. Using the Turbiscan technology and its ability to scan the sample over time, it is now possible to study and characterize all types of foam. In this week’s blog post, we look at how two different shaving foams have been characterized to compare the stability of different formulations. How does the Turbiscan work? As mentioned in our previous blog posts, the Turbiscan technology is based on Static Multiple Light Scattering, which consists of sending 880 nm near infrared light into a sample and acquiring backscattered (BS) and transmitted (T) light whilst scanning over the entire sample height. By repeating this measurement over time, the instrument enables us to measure physical stability. The signal is directly linked to the particle concentration (φ) and size (d) according to the Mie theory: 𝑩𝑺 = 𝒇(φ, 𝒅) How was the study carried out? Commercial shaving foams were analysed using the Turbiscan technology by scanning each sample at a frequency of one scan every 30 seconds for 3 hours (361 scans). All the measurements were performed at 37°C to simulate body temperature to evaluate the foam stability under real conditions. Due to the fragile structure of the foams, they were generated inside the measurement cells to avoid any sampling. What were the results? From the raw data in the graph below (figure 1), we can see a global decrease of the intensity of backscattering over the time of analysis, which is caused by a size increase of the air bubbles over time. The air bubbles coalesce together to form bigger ones. To enable the characterisation of the different shaving foams, the following parameters are calculated: • The global stability • The kinetics of bubble coalescence. In terms of global stability, it is possible to monitor the destabilization kinetics in the samples versus ageing time, due to the Turbiscan Stability Index (TSI). This sums all the variations detected in the sample (coalescence, clarification, liquid drainage, etc). At a given ageing time, the higher the TSI, the more unstable the sample. From Figure 2 & Table 1 below, we can discern that there is a less of a change in shaving foam B (coalescence of the bubbles) and therefore this sample can be considered to be more stable. Looking at the kinetics of bubble coalescence, we can see that over time, the air bubbles tend to coalesce so that their size increases until they reach a maximum then the bubbles burst and liquid is released. The Turbiscan software allows the automatic computation of the mean diameter of the air bubbles directly from the level of backscattering of the foam phase. The graph in Figure 4 below has been generated using the following parameters: According to Figure 3 and table 2 we can conclude the following:

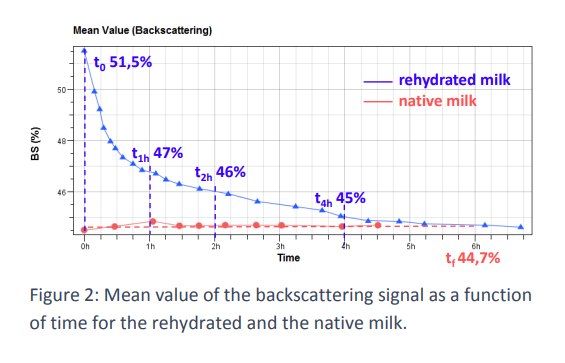

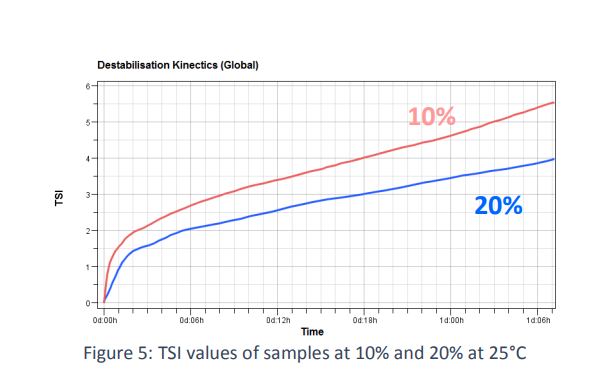

• The air bubbles in foam A are 10x larger than Foam B at the start of the experiment. • The air bubbles on the foam B coalesce at a slower rate than foam A. The optical microscopy requires many analyses to obtain accurate data. When the foam is placed between the slide and the cover glass the bubbles can interact and break differently from when they are left to change “naturally”. We have assumed that the bigger bubbles are broken whilst sampling the foam. Nevertheless, this technique is commonly used in industry and provides information on the bubbles shape and can be used to determine the bubbles mean diameter (it is necessary to take many samples for the results to be statistically valid). The shaving foams in this study were also analysed using microscopic techniques, the mean bubble size was determined after 10 experiments and was equal to about 20 μm (shaving foam B). This value can be compared to the value obtained with the Turbiscan (about 35 μm), it should be remembered that the larger bubbles are not broken during the testing with the Turbiscan, as there is no need to sample the product. Another significant advantage of the Turbiscan is that the size evolution of the bubbles is continuously measured during the foam coalescence. Conclusion In this study, 2 different shaving foams have been analysed and completely characterized using the Turbiscan technology in a very short time. Using the Turbisoft software it is possible to measure the following parameters: • Turbiscan Stability Index (Global Measurement of Stability) • Average Bubble Size at start of experiment • Change in average Bubble Size over experiment. It can be seen that all of the parameters show that foam B has better stability properties that all stem from the original smaller bubble size at the start of the experiment. The graph below summarises all the computation done during this study. If you’d like to know more about the Turbiscan technology, and how it can help with your own research, development and processes, please call us on: 01442 876777, or email: sales@fullbrook.com. In the dairy industry, milk is often dehydrated, with milk powder holding a longer shelf life than liquid milk, since it does not require refrigeration. As a result, it is easier to transport. However, dehydration must not alter the milk properties; consequently, it is important to check if the rehydrated milk has the same properties as the native milk. Another aspect is to measure the rehydration kinetics to optimize the rehydration process. In this blog post, we look at a method for assessing the kinetics and the efficiency of the rehydration of milk powder. We also analyse the stability of rehydrated milk powder. How was this study carried out? To achieve this goal, milk protein concentrate was rehydrated for 6 hours. During rehydration, a sample was taken every 10 minutes and the backscattering level was analysed with a Turbiscan LAB. The results were then compared to the backscattering level of the sample before dehydration. Rehydration is completed as soon as the backscattering level of the native and the rehydrated milk are equivalent. What were the results of the rehydration kinetics? Figure 2 below shows the evolution of backscattering level with time for the rehydrated milk. The results were compared to the backscattering level of the native milk. The graph shows that immediately after rehydration, the rehydrated milk has a much higher backscattering level than the native one (51.1 % vs 44.7 %). The backscattering level of the rehydrated milk then decreases until it reaches the level of the native milk, i.e. the same concentration and the same particle size. The rehydration is seen to be complete after 4 hours of mixing. It is interesting to note from this experiment that the rehydration process is not linear. Indeed, at the beginning of the rehydration, the backscattering level decreases quickly. After 1 hour of mixing, the signal is already reduced to 47%, meaning that 2/3 of the rehydration process has completed within an hour. The stability of rehydrated powder After rehydration, the stability of milk powder at 2 different concentrations (10 % and 20 %) was assessed for 1 day at 25°C. With the help of the Turbiscan profiles, we can identify the destabilization phenomena occurring in the samples: for both milk powders, a creaming phenomenon is occurring at the top of the sample and a clarification at the bottom. To assess global stability, all the destabilisations occurring in the sample must be considered. The Turbiscan Stability Index (TSI) was created for this exact purpose, which sums all the variations over the entire sample. As a result, if the signal varies a lot, the TSI will be high. Therefore, the higher the TSI, the lower the stability. Figure 5 shows the evolution of TSI as a function of time the graph clearly shows that the sample at 20% concentration is more stable than the 10% one. The following table displays TSI values after 30 minutes and 1 day of measurement, showing that samples can be differentiated after only 30 minutes of measurement.

Conclusion A simple method based on comparison of signals obtained with milk before and after rehydration is proposed to control the rehydration of milk powder using the Turbiscan LAB. Turbiscan LAB also allows us to compare samples in terms of stability in one click using the TSI tool; in the present study, samples can be ranked in only 30 minutes. For more information about the Turbiscan and how it can help you with your own research in the dairy industry, please contact us on 01442 876777 or email: sales@fullbrook.com. The versatility and efficacy of chromatographic techniques have made them essential in both large scale and analytical separation.

Chromatography is widely used in bioprocessing to separate protein molecules from concentrated process fluids. The centre of a chromatography system is a column, filled with a media specific to the separation being carried out. How is the Kemtrak DCP007 Photometer used for chromatography product detection? Chromatography is used for protein separation and purification in biotechnology and can require one or more chromatography steps during downstream processing. Separation through chromatography requires specialized equipment to ensure maximum yield and purity. A Kemtrak DCP007-UV photometer is optimally designed for in-line real time measurement and control, allowing the detection of a protein rich solution to be diverted for collection. With an optional NIST Validation accessory mounted it will allow the user to do a validation of instrument in-line in a simple way. How does the Kemtrak DCP007 Photometer help with measuring protein levels? Advances in bioprocessing methods have led to protein products being expressed and concentrated to higher and higher levels. Higher protein concentrations mean higher absorbance and therefore, UV analysers need the ability to measure accurately at these higher absorbance levels. While absorbance measurement is essentially linear, many traditional instruments use light sources that generate a broad spectrum of wavelengths that cause stray light to enter the measurement cell resulting in a non-linear response to protein concentration, particularly at high levels. Also, traditional light sources are sensitive to temperature, generating a lot of thermal energy, and constantly drift due to deterioration. This makes them unsuitable, particularly for fragile protein molecule work. How do I install the Kemtrak DCP007 for post-column chromatography monitoring? The Kemtrak DCP007-UV analyser will deliver accurate, reliable, and repeatable post column UV and are a minimum requirement during chromatographic separation to ensure good protein fraction purity and maximum yields. With the unique Kemtrak zero dead volume measurement cell installed at the column outlet, the Kemtrak DCP007-UV analyser can provide single or dual wavelength UV absorbance analysis, in real time, for improved control of the separation process. With this, the need for offline testing and manual analyses is greatly reduced. Furthermore, the use of solid-state light sources provides the ability to measure up to 4.5 Au at 280 nm and to monitor high concentration processes up to 90 OD linearly without “peak clipping” and the undesirable effects of “hot” and powerful UV light sources on the product. Therefore, the Kemtrak DCP007-UV is the best analyser for chromatographic separation. For more information about how the Kemtrak DCP007 can assist with your chromatography, please contact us at: sales@fullbrook.com or call: 01442 876777. Recently, we looked at how the Kemtrak DCP007-NIR can be used to improve chromatographic separations. In this week’s post, we analyse how this popular and diverse instrument can also be used to improve solvent concentration control.

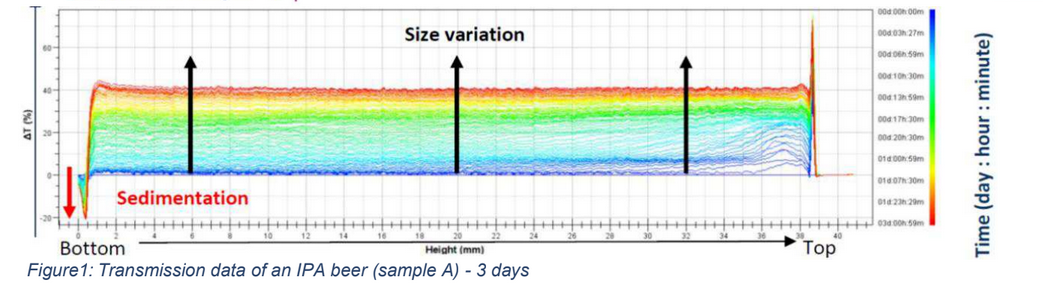

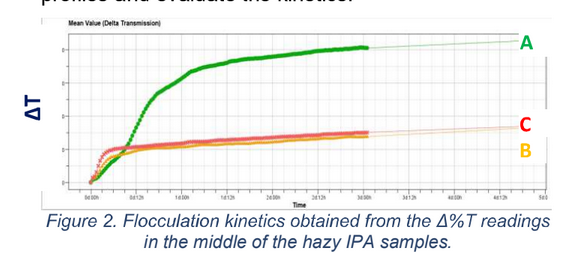

The versatility and efficacy of chromatographic techniques have made them essential in both large scale, and analytical separations. Chromatography is widely used in bio-processing to separate protein molecules from concentrated process fluids. The centre of a chromatography system is the column, filled with a media specific to the separation to be carried out. How is the technique applied? Solvent gradient control can significantly enhance peak separation and the process economy of chromatography applications. An in-line quantitative sensor permits on-line mobile phase assessment, which with controlled feedback can guarantee accurate and reproducible results. Controlled gradients minimize the effects of changing properties of the stock solvents. How was the instrument installed? Pre-Column chromatography monitoring: The Kemtrak DCP007-NIR mounted in-line before the chromatography column, continuously monitoring the solvent concentration, gives the user control over the composition delivered to the chromatography column. The online monitoring of solvent composition is more significant than measuring physical parameters like mass flow alone. As It allows the generation of batch reports that confirm the actual gradient composition and inhibits the incorrect use of a solvent. The Kemtrak hygienic measurement cells available with FDA and UPC VI approved materials, convenient zero dead volume design; contain no electronics or moving parts for ease of use. There are two versions of the Kemtrak DCP007-NIR currently available: DCP007-NIRL (850 – 1550 nm) for measurement of 0 - 100% water and solvent gradients. DCP007-NIRH (850 – 2000 nm) for trace water and hydrocarbon detection. This model incorporates a multiple stage Peltier cooled and temperature regulated photodiodes and NIR LED light source for the very best in stability and performance. For more information about this instrument and how it can help you with your chromatographic processes, please call us on: 01442 87677 or email: sales@fullbrook.com, where we will also be happy to provide you with a free, no obligation quote. Beer, one of the oldest beverages produced by humans, appeared as early as 5,000 years ago, and is one of the most widely consumed alcoholic drinks in the world, only surpassed by tea and water. Produced by the brewing and fermentation of starches, it is a complex beverage, containing a diverse mixture of carbohydrates, proteins, and aroma compounds. Unlike other manufactured beverages that can be easily fine-tuned by either adding or removing ingredients, the natural fermentation process cannot be so easily changed to achieve precise ingredient concentrations. Instead, raw ingredients and processing parameters, such as time and temperature, must be carefully adjusted to achieve the required stability and sensory profile. Unfortunately, Formulaction’s Turbiscan wasn’t developed until 1994 to help brewers adjust the stability of their beers and easily estimate shelf life and other quality parameters, such as sedimentation and clarity. The Turbiscan can be used to quantitatively predict sedimentation of yeast and proteins, haze stability, flocculation, clarity, and foam stability, all of which are key parameters for many beer types. How does the Turbiscan work? The Turbiscan® technology, based on Static Multiple Light Scattering, works by sending a light source (880nm) in to a sample and acquiring backscattered (BS) and transmitted (T) signals over the whole sample height. By repeating this measurement over time, we are able to monitor physical stability. The signal is directly linked to the particle concentration and size by the Mie theory. The Turbiscan and TSI are ‘must have’ tools for formulators for fast and quantitative measurements of stability. The Turbiscan technology has now been used for decades by formulators for stability measurements and is now recognised as a standard technique for direct stability analysis. How was the study carried out? The Turbiscan can be used to quantitatively predict sedimentation of yeast and proteins, haze stability, flocculation, clarity, and foam stability, all of which are key parameters for many beer types. In this blog post, we will highlight the utility of the Turbiscan for analysing beers at all stages of the brewing process for raw ingredient analysis, optimization of processing parameters, and rapid shelf-life determination. “Hazy” IPA stability analysis Hazy IPAs have gained significant popularity in recent years and represent a new and exciting trend for craft and large breweries. These beers are characterised by their hazy appearance that is similar to orange juice, with a taste profile that is usually quite fruity. These types of IPAs are especially prone to sedimentation due to their high turbidity (proteins, and for optimal consumer experience, the haze should be stable in a variety of storage media (cans, bottles, or kegs) at given temperatures. The early stages of this destabilization phenomenon can be detected using the Turbiscan (Figure 1). From the Turbiscan data obtained (please see Figure 1) over three days, multiple destabilisation phenomena can be detected. At the bottom of the sample vial (left side of the scan) there is a sharp decrease in transmission, indicating sediment formation. A nearly global increase in %T is also observed, indicating particle size variation - flocculation. Analysis using Turbiscan software (Turbisoft) shows the flocculation kinetics of various hazy IPAs (Figure 2) allowing us to compare different profiles and evaluate the kinetics. Samples A, B, and C were of the same beer, but samples came from different batches. From this data, the stability of the batch obtained on day A was significantly lower than other batches (days B and C). The Turbiscan helped the brewery to quickly identify the root cause of the destabilisation. In addition to monitoring changes over time to predict beer stability, initial clarity can be swiftly determined using the Turbiscan (Table 1). As different beers will vary in their clarity, criteria can be established for acceptable initial raw transmission value (at t=0) as a method for assessing initial quality. This type of data allows brewers to assess batch stability in a fraction of the time compared to a subjective visual test. With changing consumer tastes, it is important to have the flexibility to modify ingredients and develop new brews while ensuring stability and performance are maintained.

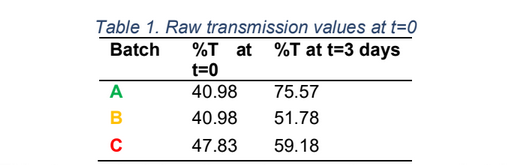

How were the quality parameters monitored during the brewing process? Process parameters must be carefully adjusted and maintained to achieve the desired properties. By determining the optimum time and temperature for each step in the process, energy and time needed can be reduced. The Turbiscan can be used to assess quality parameters even at early stages of the brewing process. One example of this is the analysis of wort clarity and the influence of processing temperature. Wort is the mother liquor and the Turbiscan can be used to monitor the clarification, and determine clarification kinetics at various temperatures. A short 10-minute test allows the identification of the differences between the sample behaviours. By plotting the change in transmission over time, the Turbiscan can help to analyse clarification kinetics at different temperatures. By rapidly determining the rates of clarification in small test batches, the conditions can be optimized for mass production. What are the properties of beer foam? Beer foam, also known as the head, is formed from the naturally produced carbon dioxide during fermentation. Beer foam can significantly affect the sensory experience and imparts a creamy quality with a sense of fullness. Certain hydrophobic proteins are known to increase foam stability, providing a longer softening effect on the palate. However, ethanol can inhibit foam formation. Several types of beers were studied regarding foam formation over time. Unsurprisingly, the beer with the lowest alcohol content (E) produced the most stable foam, only decreasing to 20% of the original volume after 400 s. At the same time, beer F showed good foam stability for its moderate alcohol content. Also, when compared to Beer B, which contained the same amount of alcohol but had lower foam stability than beer F, we can see that the use of a different container can have an impact on final foam quantities. Looking more closely at the Turbiscan data, the drainage kinetics of the foam can be plotted alongside the growth of the liquid layer. Since the Turbiscan measures the backscattering and transmission simultaneously, information on both the foam (backscattering) and beer (transmission) can be obtained from a single scan or series of scans without having to switch reading modes. This means the Turbiscan can be used to obtain detailed kinetics of foam stability and allow the brewer to adjust the beer to achieve the desired characteristics. This study demonstrates the capability of the Turbiscan to characterise beers and optimise brewing parameters. The results provide accurate, quantitative data for beer stability analysis and removes the estimation associated with visual stability observations. This high-resolution analysis can accelerate the stability analysis timeframe from many days or weeks to a couple hours for rapid shelf-life determination. In turn, this helps move projects to completion at a much faster rate than traditional methods. The Turbiscan has proven to provide fast and accurate results that can be applied to all types of beers, including traditional varieties and emerging trends such as hazy IPAs. For more information and advice on how the Turbiscan can be used to characterise beer stability, and help improve your own formulations, please contact us on: 01442 876777 or email: sales@fullbrook.com. In this week’s blog post, we look at the quality control of raw materials in the cosmetics industry, and how the Turbiscan Classic can be used to assess this. Formulation development is a vital activity for many industries, including pharmaceuticals, paints, and coatings. As sales of formulated products amount to approximately £180 billion per year in the UK, getting formulations “right” is a crucial and valuable goal. Stability is a crucial attribute for many products with a direct impact on performance, shelf-life, kerb appeal and ultimately, worth. A systematic approach to understanding and developing stability can therefore be extremely helpful in improving the likelihood of success in long term stability trials, and accelerating formulation. Part of this process depends on the quality of the ingredients. This is because the nature and the quality of a constituent in a formulation may influence its stability. As a formulator, you need to test the stability of your emulsions, suspensions, and foams with different types of raw materials. When dealing with natural products, the difference in quality can be more noticeable when moving from one supplier to another. To examine this, the effect on the stability of two cosmetic emulsions via the introduction of Jojoba oil from different suppliers was analysed using the Turbiscan Classic. How was the study carried out? Two kinds of emulsion, a Sport lotion and a Sensitive lotion were prepared with Jojoba oil from different suppliers: • with oil noted 1 • with oil noted 2 Samples number: 4 Analysis volume: 6 ml Temperature of analysis: 43°C Analysis Duration: 24 hours Two hours were needed to bring the samples to the required temperature (43°C). The curve after 2 hours of analysis was selected as a reference. The subsequent traces show the changes in back scattered light intensity (%, y-axis) on the tube height (mm, x-axis) as a function of time (the last curve is always displayed in red). What were the results of the study? The profiles obtained show different kinds of backscattering change: • NO significant backscatter change at the top of the samples prepared with oil 1, characteristic of no change in this zone (please see Figure 1 below). • a backscattering decrease at the top of the samples prepared with oil 2, characteristic of a clarification of the samples in this zone (please see Figure 2 below). The calculation of the slope of the graph over 12 hours allows the calculation of the destabilisation speed as a function of the Jojoba oil type used (Figure 4).

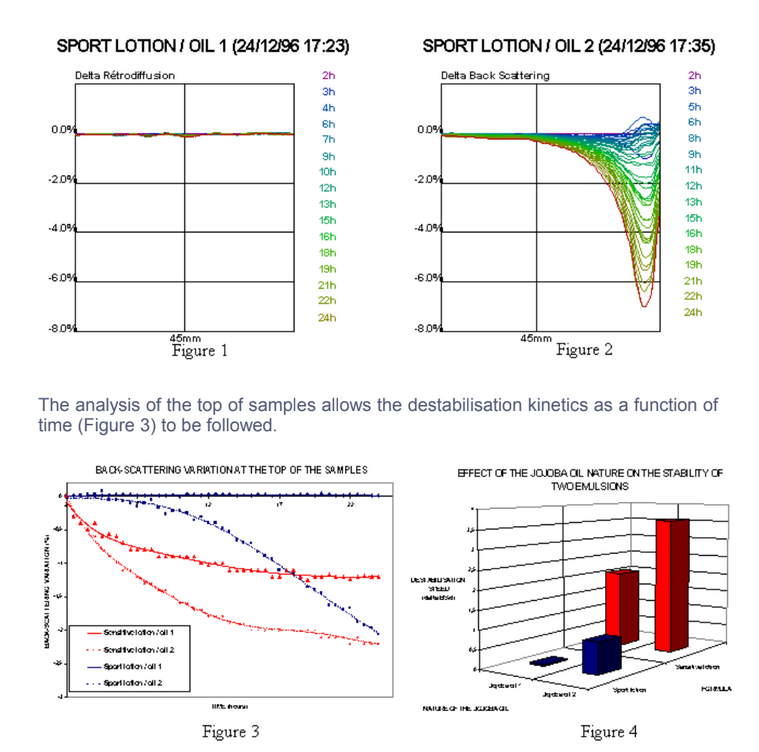

The jojoba oil 1 used in both formulations made more stable emulsions than Jojoba oil 2. This quality difference can be explained by the different oil extraction methods employed by the different suppliers. In conclusion, the Turbiscan range can detect particle migration phenomena in a few hours and allows for a quantitative comparison of the results to be made for each sample. It is, therefore, a useful tool for those formulators looking to study the effect of raw material variation on their samples. For more information about the Turbiscan and how it can help your own formulations, please email: sales@fullbrook.com or call: 01442 876777. In this week’s blog post, we discuss how Kemtrak’s popular photometer can be used to improve the efficiency of chromatographic separation processes. What are chromatographic techniques? Chromatography is widely used in bioprocessing to separate protein molecules from concentrated process fluids. The centre of a chromatography system is a column, filled with a media specific to the separation being carried out. The versatility and efficacy of chromatographic techniques have made them a crucial part of both large scale and analytical separations. The current methods of chromatographic separation are as follows: Gel filtration – refers to sorting the material by molecular size. The physical dimensions of the molecule determine the separation because proteins are naturally spherical. This means the molecular weight of the protein will be proportional to its size, allowing for separation based on this property. Larger molecules pass more slowly through the column media, while smaller molecules pass through more quickly. Ion exchange – refers to sorting the material by electrical charge. Separation works by opposite charge attraction and like charge repulsion. Using a specific charge within the column media allows for attraction and binding of the molecule(s) of interest. Hydrophobic interaction – refers to sorting the material by degree of Hydrophobicity. Separation relies on polar (hydrophilic) molecules “sticking” together and repelling those which are non-polar (hydrophobic). Affinity - this method uses a bio-specific binding site. This is a section of a molecule in which the shape and distribution of charged and hydrophobic groups allow for highly specific binding to a corresponding site on another molecule. The fit between the two sites is analogous to a lock and key. How does chromatography work? Chromatography is a process for separating components of a mixture. To start the process, the mixture is dissolved in a substance called the mobile phase. This then carries it through a second substance called the stationary phase. The different components of the mixture travel through the stationary phase at different speeds, causing them to separate from one another. The nature of the specific mobile and stationary phases determines which substances travel more quickly or slowly, and this is how they are separated. These different travel times are known as retention times. A chromatography gel is designed to have one half of this lock and key (the ligand), making it stationary within the column. As the product solution is passed through column, the specific mating molecules are bound in place until they are eluted from the column. Examples of affinity interactions include the binding between antibodies and antigens, and enzymes and substrates. The molecular properties utilised in chromatographic separation can be seen in the figure below: Separation through chromatography requires highly specialized equipment to ensure maximum yield and purity. A system may include a variety of instruments and sensors for pre - and post - column control.

Nearly all proteins absorb UV light at 280 nm, the primary reason for this is due to the aromatic amino acids, e.g. phenylalanine, tryptophan, tyrosine, and histidine. How does installing a Kemtrak DCP007 help improve chromatographic processes? Installing a Kemtrak DCP007-UV photometer, measurement cell at the column outlet, allows the presence of proteins to be detected, and therefore collection/pooling to begin. It is vital that any UV analyser has no dead or hold up volume to ensure crisp, sharp peaks are detected. UV analysers utilizing measurement cells with internal hold up volumes can lower the purity of the collected protein because of dilution. Dilution blurs sharp peak detection lines, and can cause lower yields. Using a Kemtrak DCP007-NIR photometer, mounted pre-column to determine solvent concentration/composition, allows for a feedback control of the solvent “mobile media” feed through the column, and increases the accuracy and repeatability of the chromatography system. With the unique zero dead volume Kemtrak measurement cell installed, the Kemtrak DCP007 analyser can provide single or dual wavelength absorbance analysis, in real time, for improved control of the chromatographic separation processes. Therefore, the Kemtrak DCP007 is the recommended analyser for chromatographic separations. To find out more about the Kemtrak DCP007 (UV or NIR) Photometer, please visit our website: or call: 01442 87677 to discuss your requirements further. We will also be happy to provide a free, no obligation quote. |

C HumphreysOctober 2016 Fullbrook Systems Ltd move to new premises in Hemel Hempstead. After being in the same offices for many years the company moved to more suitable premises Archives

February 2023

Categories |

RSS Feed

RSS Feed