|

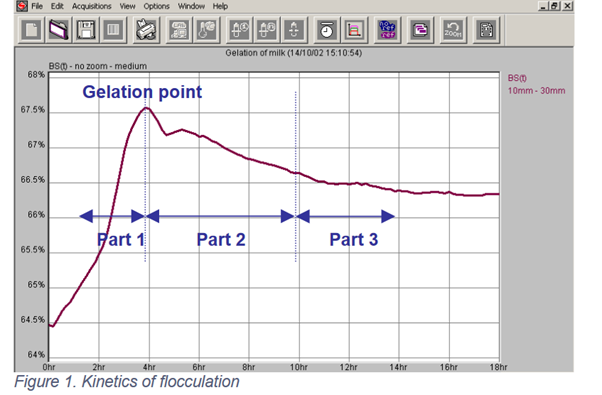

Yoghurt is a popular foodstuff made by the inoculation of milk with bacteria, which, between 42 and 44°C, will grow and reject some lactic acid. This acid is responsible for the coagulation of the casein micelles and the gelation of milk into yoghurt. The study of this gelation process is usually performed by measuring pH. However, the variation of pH is quite small (from 6.5 to 4.5) and does not provide much information about the actual process involved. In this blog post, we look at the formation of yoghurt with a Turbiscan LAB, which stores the sample in a thermoregulated area. This allows the maintenance of the sample at the temperature required for the growth of the bacteria. The analysis below allows a close follow-up, in real time, of the gelation process and can give additional information regarding the measurement of the syneresis of the product and its stability with time. How was the study carried out? The yoghurt was made directly in the Turbiscan Lab measurement cells. 20 mL of UHT whole milk was put in the cell and left at 43°C for one hour. A ferment, containing Lactobacillus Bulgaricus and Streptococcus Thermophilus, was diluted in milk at 25g/L, which was then used to inoculate the pre-heated milk. The process of gelation of milk into yoghurt was followed for 18 hours, with one scan performed every 10 minutes at 43°C. A measurement of the pH was made in at the same time, to correlate results produced from both techniques. What were the results of the study? Gelation of milk giving yoghurt is due to the coagulation of casein micelles, forming a network that results in the solidification of milk. This process is simple to visualise using the Turbiscan LAB and study the evolution of the backscattering level with time. This means it is possible to calculate the kinetics of flocculation, by following the backscattering level in the middle of the sample (please see Figure 1 below). We can observe three different regimes:

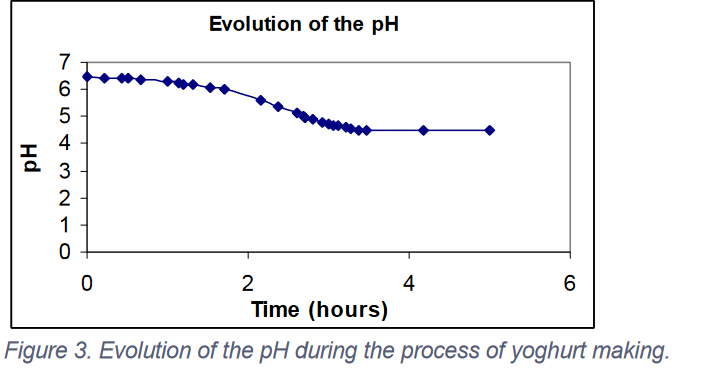

We see a decrease of the pH due to the growth of the bacteria during the gelation process, which stabilises after 4 hours, and corresponds to the end of the bacteria growth seen on the backscattering profile. However, it is quite difficult to obtain more information on the actual process and its kinetics from the pH curve.

In conclusion, the Turbiscan Lab is the ideal instrument to use if you are working in the dairy industry. It enables to you follow in detail the gelation process that produces yoghurt from milk. The equipment allows you to optimise the process, and can be used for a stability study of the product with time (i.e. phase separation, syneresis, etc.). To find out more about the Turbiscan Lab and its applications, please call us on: 01442 876777 or email: sales@fullbrook.com. We will also be happy to provide you with a free, no obligation quote, and test some samples for you.

0 Comments

Leave a Reply. |

C HumphreysOctober 2016 Fullbrook Systems Ltd move to new premises in Hemel Hempstead. After being in the same offices for many years the company moved to more suitable premises Archives

February 2023

Categories |

RSS Feed

RSS Feed