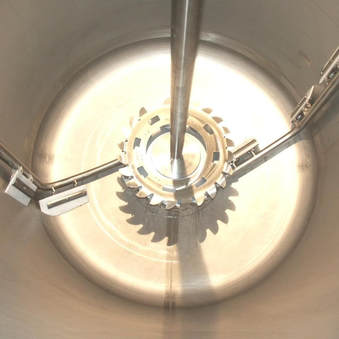

ADV Kreis Dissolvers

Fixed vessel - 3,000 to 25,000l

|

Main features:

|

Type ADV Motor power Rotation speed Batch size *Useable volume **

ADV 242-30 FU 22 kW 100 - 1650 1/min 300 - 1.000 kg 250 - 750 L

ADV 332-41 FU 30kW 100 - 1500 1/min 350 - 1.250 kg 250 - 1.000 L

ADV 411-50 FU 37 kW 90 - 1400 1/min 500 - 1.500 kg 400 - 1.200 L

ADV 491-61 FU 45 kW 90 - 1400 1/min 600 - 2.000 kg 500 - 1.600 L

ADV 601-75 FU 55 kW 85 - 1250 1/min 800 - 2.500 kg 600 - 1.900 L

ADV 790-100 FU 75 kW 70 - 1000 1/min 1.000 - 3.200 kg 800 - 2.500 L

ADV 1000-122 FU 90 kW 70 - 950 1/min 1.250 - 4.000 kg 1000 - 3.100 L

ADV 1500-150 FU 110 kW 60 - 850 1/min 1.500 - 5.000 kg 1.200 - 3.900 L

ADV 1500-180 FU 132 kW 55 - 800 1/min 2.000 - 6.000 kg 1.600 - 4.600 L

ADV 1700-218 FU 160 kW 50 - 700 1/min 2.500 - 7.500 kg 1.900 - 5.800 L

ADV 2000-272 FU 200 kW 50 - 600 1/min 3.200 - 11.000 kg 2.500 - 8.500 L

ADV 2000-340 FU 250 kW 50 - 600 1/min 4.000 - 15.000 kg 3.100 - 11.500 L

ADV 3000-430 FU 315 kW 40 - 480 1/min 13.000 - 19.500 kg 10.000 - 15.000 L

* Dependent on viscosity | ** Density of approx. 1,3 kg/dm3 | FU = Frequency converter

ADV 242-30 FU 22 kW 100 - 1650 1/min 300 - 1.000 kg 250 - 750 L

ADV 332-41 FU 30kW 100 - 1500 1/min 350 - 1.250 kg 250 - 1.000 L

ADV 411-50 FU 37 kW 90 - 1400 1/min 500 - 1.500 kg 400 - 1.200 L

ADV 491-61 FU 45 kW 90 - 1400 1/min 600 - 2.000 kg 500 - 1.600 L

ADV 601-75 FU 55 kW 85 - 1250 1/min 800 - 2.500 kg 600 - 1.900 L

ADV 790-100 FU 75 kW 70 - 1000 1/min 1.000 - 3.200 kg 800 - 2.500 L

ADV 1000-122 FU 90 kW 70 - 950 1/min 1.250 - 4.000 kg 1000 - 3.100 L

ADV 1500-150 FU 110 kW 60 - 850 1/min 1.500 - 5.000 kg 1.200 - 3.900 L

ADV 1500-180 FU 132 kW 55 - 800 1/min 2.000 - 6.000 kg 1.600 - 4.600 L

ADV 1700-218 FU 160 kW 50 - 700 1/min 2.500 - 7.500 kg 1.900 - 5.800 L

ADV 2000-272 FU 200 kW 50 - 600 1/min 3.200 - 11.000 kg 2.500 - 8.500 L

ADV 2000-340 FU 250 kW 50 - 600 1/min 4.000 - 15.000 kg 3.100 - 11.500 L

ADV 3000-430 FU 315 kW 40 - 480 1/min 13.000 - 19.500 kg 10.000 - 15.000 L

* Dependent on viscosity | ** Density of approx. 1,3 kg/dm3 | FU = Frequency converter

|

Options:

|

Applications:

|